Food & Beverage Industry Cleanrooms

The food and beverage industry’s high standard of hygiene requires the use of CleanZones’ cleanrooms. Our cleanrooms assist companies in the food and beverage industry follow the strict rules and standards for products marketed around the world.

Food and beverage grade cleanrooms help minimize the number of germs and fungi making the production process and end products safer and cleaner. Using a cleanroom also increases shelf life allowing for longer storage, higher efficiencies and higher margins.

A cleanroom is a controlled environment where food and beverage products are processed and packaged. The contaminants inside a cleanroom are highly controlled with respect to airborne particulates, temperature, humidity, air pressure, airflow patterns, living organisms and lighting. The level to which particulates need to be removed depends on the standards set by our customers.

Phone: 888-399-2464

Food and Beverage Cleanroom Applications

- Meat processing and packaging cleanrooms

- Soft drink cleanrooms

- Vitamin manufacturing

- Food processing and packaging cleanrooms

- Dairy processing and packaging cleanrooms

- Seafood processing and packaging cleanrooms

- Chocolate and candy cleanrooms

- Frozen foods cleanrooms

- Cold storage cleanrooms

- Confectionary and snacks cleanrooms

- Brewery and fermentation cleanrooms

- Enclose manufacturing line for fruit and vegetables

- Enclose bottling line

- Protection of liquid product filling

- Protection of spawn strains against contamination

- Gluten-free cleanrooms

- Lactose-free cleanrooms

- Allergen-free cleanrooms

CleanZones Food & Beverage Cleanrooms

While useful throughout the food and beverage industry, CleanZones’ cleanrooms are especially helpful to ensure your product remains allergen free. Gluten, lactose and other allergens can all be filtered using our cleanroom systems.

At CleanZones we offer a variety of design configurations and construction materials to meet exact specifications. All cleanrooms feature a 2 X 4 HEPA or ULPA fan filter unit, 2x4 Cleanroom LED Flat Panel Edge Lit Light Troffers, ceiling tiles, doors and wall materials.

Cleanroom Types:

- Softwall cleanrooms

- Hardwall cleanrooms

- Semi Hardwall cleanrooms

Additional Food and Beverage Cleanroom Features:

At CleanZones we work with our clients to design a Food & Beverage cleanroom with all of the features you need and nothing you don’t. We design, engineer, install and certify all food and beverage cleanroom features.

- Air showers

- Laboratory casework

- Unidirectional Class 100 work stations

- Fan filter units

- Wet process stations

- Negative flow exhausting work stations

- Pass through cabinets

- Garment cabinets

- Bulkheads

- Process utilities

- Gas cabinets

- Gas panels

- High purity piping

- Air pollution control systems

- N2 generators

- Deionized water systems

- Hazardous gas detection systems

- Ionization equipment

- Antistatic cleanroom supplies

- Static control products

- HVAC systems

- HEPA filtration systems

CleanZones Food & Beverage Cleanroom Experience

- Softwall Cleanroom for Food container manufacturing

- Laboratory Casework and HEPA filtered ceiling

- Semi-Hardwall Cleanroom for Food and Beverage flavoring sampling

- Semi-Hardwall Cleanroom for Hops processing, testing and inspection

- Softwall Cleanroom for Dietary Supplement manufacturing Softwall Cleanroom

- Softwall Cleanroom for testing natural foods production

CleanZones Standards

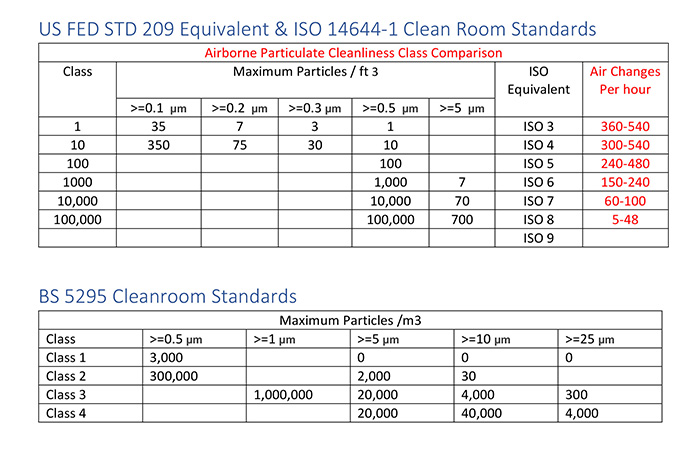

We design, engineer, manufacture and certify food and beverage cleanrooms to our customers’ exact standards.

CleanZones’ Process

At CleanZones we specialize in custom products without the custom cost. We ensure that our customers receive products that match their exact requirements, on time and on budget.

- Initial consultation: expert, comprehensive evaluation of needs and required air quality level

- Engineering and design: experienced staff provide the necessary CAD drawings

- Manufacturing: manufacturing process to your exact specs and budget

- Installation: optional installation of the entire system or expert guidance and support

- Certification and testing: all products tested to assure compliance with government and industry standards

- Maintenance: optional maintenance customized to requirements including annual maintenance contracts